Hall Contracting was engaged to carry out the dredging of the tailings pond at FMG’s port facility in Port Hedland, Western Australia. The project involved dredging over 4.5million m³ of tailings a distance of 2.4km, in order to prepare for the expansion of the iron ore facility. The fine tailings material was produced from the land reclamation and berth construction carried out by Jan De Nul’s large cutter suction dredge ‘Leonardo Da Vinci’.

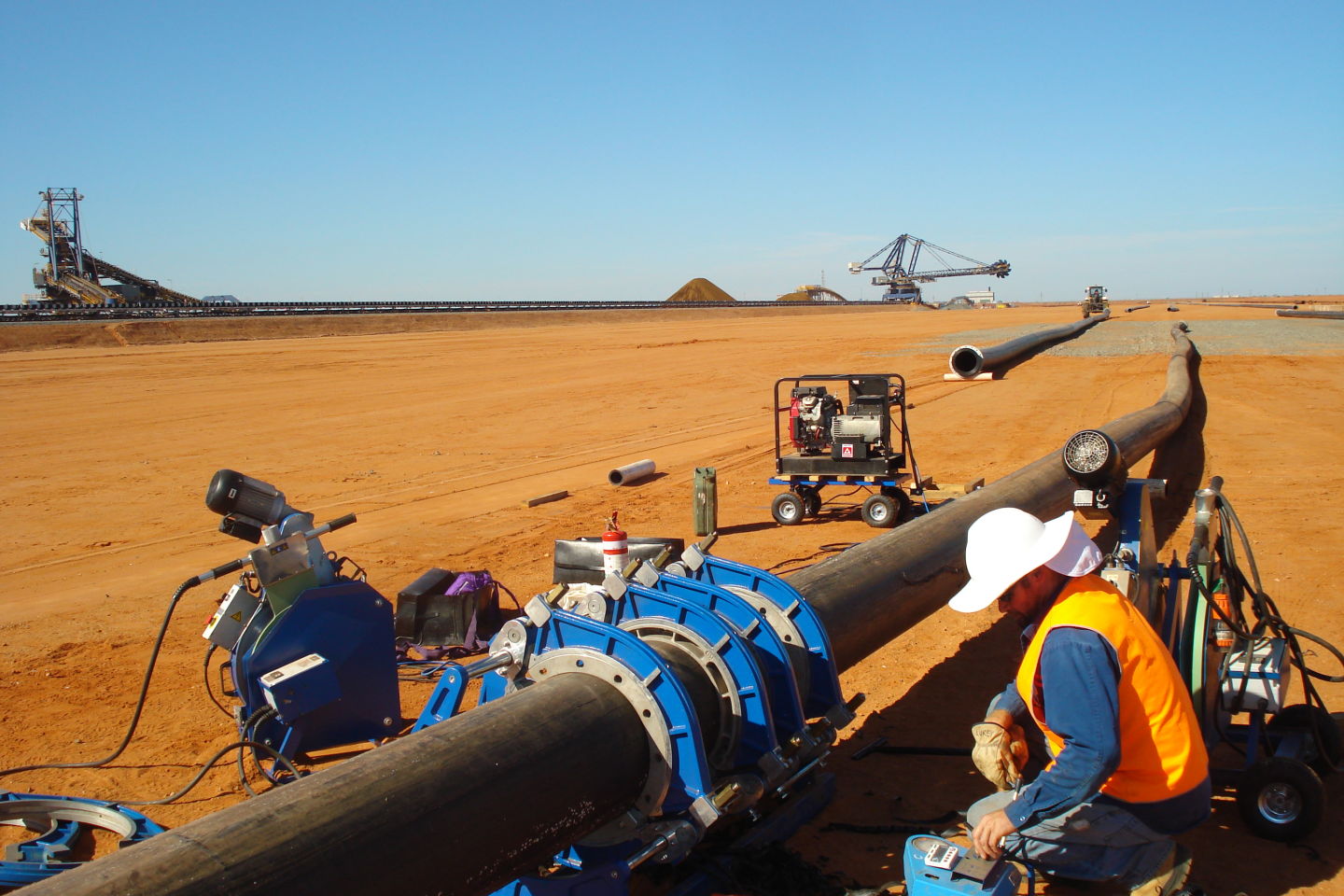

In order to maintain water quality and meet strict environmental standards, Hall Contracting pumped water back to the dredge pond to create an effective ‘closed circuit’. Working 24/7, Hall used two of its Beaver 1200 cutter suction dredges and 2 booster stations to move the material. The timely performance of the contract ensured that Fortescue Metals avoided costly delays to the capital works program.